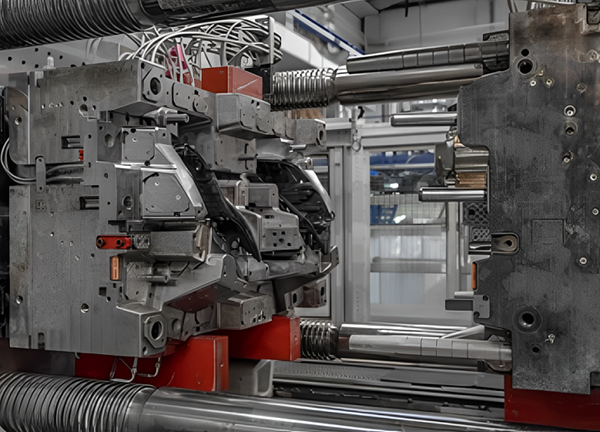

Cold chamber die casting is a widely used metal-forming process in modern manufacturing, particularly for the efficient processing of high-melting-point metals such as aluminum, magnesium, and copper. This article systematically introduces the core characteristics, advantages, and limitations of cold chamber die casting, along with its typical applications across various industries, helping manufacturers make informed production decisions.

The defining feature of cold chamber die casting is its high-pressure injection technology, typically exceeding 10,000 psi (~70,000 kPa). This ensures rapid and uniform filling of complex mold cavities, enabling high-fidelity forming of intricate structures, even those with wall thicknesses as thin as 0.5 mm. The high pressure also compacts the metal structure, significantly improving part density and mechanical properties.

Since the melting furnace and injection chamber are separate in cold chamber die casting machines, they are less susceptible to erosion from molten metal. This makes the process particularly suitable for high-melting-point metals such as aluminum (660°C), magnesium (650°C), and copper (1085°C). Compared to hot chamber die casting, cold chamber die casting expands material options, especially in automotive and aerospace applications.

Cold chamber die casting features a precise control system, including:

Injection pressure: Divided into primary filling pressure and secondary intensification to improve mold-filling quality and reduce shrinkage defects.

Injection speed: Typically controlled at 15–70 m/s at the gate, directly affecting surface finish and structural integrity.

Mold temperature: For aluminum alloys, maintaining a mold temperature of 200–220°C helps minimize thermal stress and enhance dimensional accuracy.

This multi-parameter control capability allows cold chamber die casting to adapt flexibly to diverse product requirements, from micro-components to large structural parts.

Although cold chamber die casting has a slightly longer cycle time than hot chamber die casting, its automation potential is greater. Modern die casting units often incorporate robotic arms for automated pouring, part extraction, and mold spraying, significantly boosting efficiency. An advanced cold chamber die casting machine can produce hundreds of aluminum alloy parts per hour, making it ideal for medium- to large-scale production.

Advantages

High Strength and Lightweight: Aluminum die-cast parts can achieve tensile strengths exceeding 300 MPa while weighing only one-third as much as equivalent steel parts, making them ideal for lightweight designs.

Superior Surface Finish: Parts exhibit smooth, high-quality surfaces, often eliminating the need for secondary machining.

Complex Structures in a Single Step: Multi-cavity, intricate designs can be formed in one operation, reducing assembly and welding steps.

Limitations

High Equipment and Mold Costs: Significant upfront investment makes the process more suitable for high-volume production to amortize costs.

Limited Material Range: Primarily used for high-melting-point metals; low-melting-point alloys (e.g., zinc) are better suited for hot chamber die casting.

Potential Porosity Defects: Improper filling speed or venting can lead to air entrapment, requiring vacuum-assisted casting or post-treatment (e.g., impregnation) to mitigate.

Powertrain Components: Engine blocks, cylinder heads, and pistons that must withstand high temperatures and pressures.

Structural and Housing Parts: Suspension arms, steering knuckles, and transmission housings benefit from aluminum’s weight reduction.

Case Study: Tesla’s Model Y uses cold chamber die casting for its integrated rear underbody, drastically reducing part count and enhancing body rigidity.

Magnesium Structural Parts: Seat frames and door brackets that require lightweight durability.

High-Thermal-Conductivity Components: Copper alloy heat sinks and impellers for improved cooling efficiency.

Heat Sinks and Enclosures: Aluminum’s excellent thermal conductivity and mechanical strength make it ideal for CPU coolers and 5G base station housings.

Hydraulic Valve Blocks and Pump Housings: Complex internal channels can be cast directly, minimizing post-processing.

Corrosion-Resistant Housings: Copper alloys extend service life in chemical processing equipment.

Appliance Housings and Internal Components: Coffee makers, razors, and power tool casings benefit from aesthetic appeal and durability.

Sports Gear Parts: Magnesium bicycle hubs combine lightness with high strength.

Cold chamber die casting is evolving toward higher performance and smarter manufacturing:

Vacuum Die Casting: Evacuates air from the mold cavity before injection, reducing porosity and enhancing mechanical properties.

Semi-Solid Die Casting: Uses partially solidified metal slurry for more uniform filling, ideal for high-precision parts.

Smart Monitoring Systems: Real-time feedback from pressure sensors and temperature controls optimizes injection parameters, improving yield rates.

Cold chamber die casting has become a vital process in modern manufacturing due to its compatibility with high-melting-point metals, high-pressure precision forming, and automation potential. It meets diverse demands—from automotive lightweighting and aerospace strength to electronics thermal management—while continuously expanding its applications through innovation.

As new materials and smart manufacturing technologies advance, cold chamber die casting will play an even more critical role in high-end production. Manufacturers should evaluate material properties, design complexity, and production volume when selecting a process, with cold chamber die casting standing out as an optimal choice for high-performance, large-scale production.

If you need cold chamber die casting products, contact EDT.

We specialize in aluminum alloy die casting and zinc alloy die casting with a wide range of cold chamber die casting machines. With 20 years of production experience, we deliver reliable quality and precision.

Visit us today!