Die casting molds endure extreme conditions—high temperature, pressure, and speed—making material selection a critical factor in production efficiency and product quality. One common question is: should you use stainless steel for molds? or are there better alternatives? In this guide, we break down the pros and cons and help you make informed decisions for your die casting operations.

While stainless steel is corrosion-resistant, it is generally not the best option for die casting molds. It has poor thermal fatigue resistance and lower thermal conductivity compared to traditional hot work tool steels. Stainless steel is also more difficult to machine and can crack or erode under the impact of molten aluminum or copper. Thus, it's typically reserved for mold components rather than main cavities.

Material selection depends on several factors: casting metal type, operating temperature, stress conditions, part geometry, and production volume. Below are some widely used mold steels and their key properties:

H13 is the most commonly used steel for aluminum die casting molds. It offers balanced high-temperature strength, toughness, and fatigue resistance. It is ideal for small-to-medium production runs and offers excellent value, especially in domestic variants.

8418 is known for its outstanding resistance to thermal fatigue and high purity. It’s commonly used for large, complex molds that require extended tool life—such as automotive engine housings. Its price is higher, but so is its lifespan—often 2–3 times that of H13.

These steels offer better toughness and heat stability than H13. With higher molybdenum content, they are suitable for molds with complex structures and demanding load conditions.

These premium steels are leaders in heat strength, thermal conductivity, and erosion resistance. While expensive, they are ideal for extreme conditions or ultra-high-volume production.

· Melting point: ~400°C; low thermal load

· Materials: 3Cr2Mo, P20 pre-hardened steel, H13

· Key factors: corrosion resistance and surface finish

· Melting point: 650–700°C; significant thermal stress

· Materials: H13, 8418, Dievar, DAC55

· Key factors: thermal fatigue resistance, toughness, heat conductivity

· Melting point: >900°C; short mold lifespan

· Materials: FS443, 3Cr2W8V, Y4, powder metallurgy steels

· Key factors: high-temperature strength, erosion and oxidation resistance

1、Cost-driven strategy: Opt for lower-moly steels like H13 for low-volume or prototype molds.

2、Durability-first strategy: Choose DAC55, 8418 for extended life and high-performance applications.

3、High-heat environments: For molds without water cooling or working with pure aluminum or copper, use QRO90, Y4, or similar materials.

4、High-strength applications: For molds with fine cores or deep cavities, consider high-hardness steels like LG or W360.

5、Large molds: Use tough, low-alloy steels like H11 or 2343 to avoid cracking under thermal expansion.

Reminder: Mold longevity is not only determined by material choice but also by design, heat treatment, alloy content, and refining quality. Avoid cutting costs at the expense of mold performance, or you risk premature failure.

Surface treatments: PVD coatings (AlCrN, TiAlN), nitriding, and boriding can improve hardness and erosion resistance.

Purity and microstructure: ESR (electroslag remelting) and powder metallurgy processes enhance fatigue resistance and reduce defects.

Pre-hardened materials: Pre-heat-treated steel simplifies mold making and minimizes warping risk.

There is no single “best” mold steel—only the most appropriate one for your specific needs. Whether it’s cost, lifespan, or mechanical performance, selecting the right material is about balance. Stay informed, work with quality suppliers, and base decisions on long-term ROI—not just upfront cost.

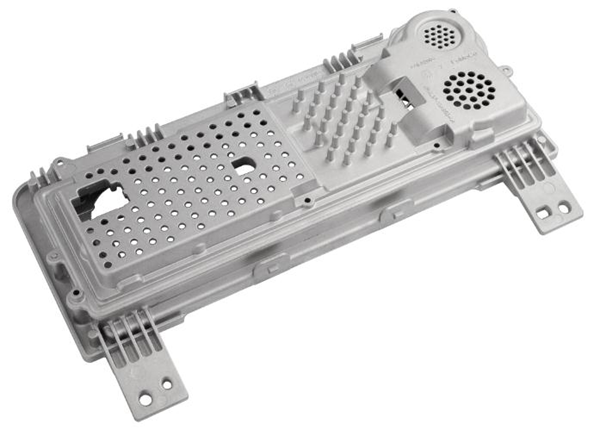

EDT Diecasting Technology (Suzhou) Co., Ltd. is an Italian-owned manufacturer specializing in zinc and aluminum alloy die casting. Located in Suzhou High-tech Zone, our 9,000 m² facility features advanced hot and cold chamber machines, multi-slide systems, and vacuum die casting technology.

Our products serve industries such as automotive, furniture, telecom, and construction. EDT holds ISO 9001 and IATF 16949 certifications, and was recognized as an “Innovative SME” in 2022 and “Technology SME” in 2023.

With 21 patents to date, EDT is committed to delivering high-performance, precision-engineered die casting components to clients worldwide. Contact us for your next mold design or die casting project.