Aluminum die casting is a highly efficient manufacturing process widely used in automotive, aerospace, electronics, and consumer goods industries. The performance and longevity of die-cast parts heavily depend on the mold material used. This guide explores the best materials for aluminum die casting molds, their properties, and selection criteria to help aluminum die casting manufacturers optimize production efficiency and mold lifespan.

Aluminum die casting molds endure extreme conditions:

-High temperatures (600–700°C molten aluminum)

-High pressure (up to 100+ MPa injection force)

-Thermal cycling (rapid heating & cooling)

-Abrasion & corrosion (from molten metal flow)

Key Properties for Mold Materials:

-Heat resistance – Retains hardness at high temps (Red hardness)

-Thermal fatigue resistance – Prevents cracking from repeated heating/cooling

-High thermal conductivity – Efficient heat dissipation

-Wear & corrosion resistance – Withstands molten aluminum erosion

-Machinability & polishability – Ensures precise mold surfaces

① H13 Tool Steel (4Cr5MoSiV1) – The Industry Standard

-Composition: 5% Cr, 1.5% Mo, 1% V

-Hardness: 45–50 HRC (after heat treatment)

-Advantages:

·Excellent thermal fatigue resistance

·Good toughness & machinability

·Cost-effective for high-volume production

-Best for: General-purpose aluminum die casting

② FT416ESR Steel – Premium Performance

-Enhanced version of H13 (Electro-Slag Remelted)

-Advantages:

·Superior purity & uniformity (fewer defects)

·Better thermal conductivity than standard H13

·Longer mold lifespan in high-stress applications

-Best for: High-precision & long-run production

③ 8407 Steel (Uddeholm) – High Polishability

-Premium European tool steel

-Advantages:

·Exceptional surface finish (low sticking risk)

·High wear resistance

·Good thermal shock resistance

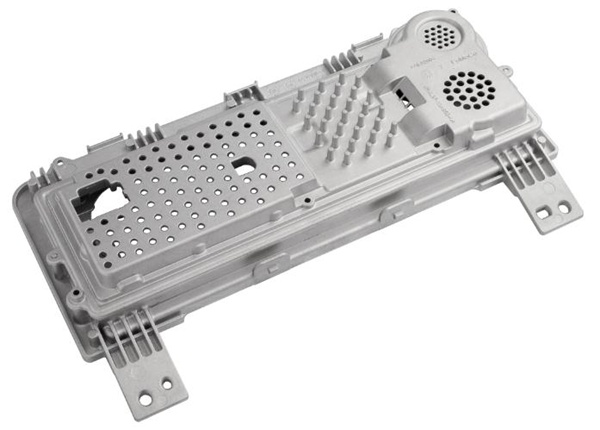

-Best for: Automotive & consumer electronics (cosmetic parts)

④ 8418 Steel – High Toughness & Heat Resistance

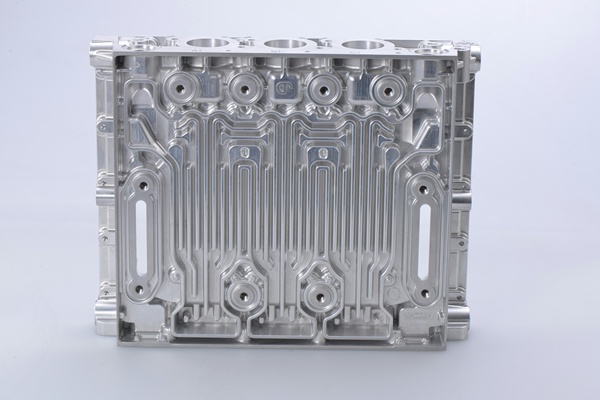

-Optimized for large & thick-walled castings

-Advantages:

·Higher molybdenum (Mo) content for better high-temp strength

·Reduced thermal cracking risk

-Best for: Heavy-duty aluminum casting (e.g., engine blocks)

⑤ 3Cr2W8V Steel – Traditional Option

-Older material, still used in some applications

-Advantages:

·Good red hardness (retains strength at high temps)

-Disadvantages: Lower toughness vs. H13

-Best for: Low-cost molds (small batches)

High-Thermal-Conductivity Steels (e.g., Y10, HM3)

-Faster heat dissipation → Reduced cycle time

-More uniform mold temperature distribution

Surface Treatments for Longer Mold Life

-Nitriding: Increases surface hardness (up to 70 HRC)

-PVD/CVD Coatings: Reduce aluminum sticking (e.g., TiN, CrN)

-Shot peening: Improves fatigue resistance

Factor | Recommended Material |

High-volume production | H13 / FT416ESR |

High surface finish needed | 8407 / Polished H13 |

Large & thick castings | 8418 / Modified H13 |

Budget constraints | 3Cr2W8V (for prototypes) |

Extreme thermal cycles | FT416ESR + Nitriding |

- Proper heat treatment (quenching & tempering)

- Optimized cooling channels (conformal cooling design)

- Regular maintenance (cleaning, corrosion protection)

- Use high-quality release agents (reduce sticking & wear)

Selecting the right aluminum die casting mold material depends on production volume, part complexity, and cost considerations. H13 steel remains the most widely used choice, while FT416ESR and 8407 offer superior performance for demanding applications. By combining advanced materials, coatings, and proper maintenance, aluminum die casting manufacturers can maximize mold life and production efficiency.

For high-quality die casting molds, always consult with material suppliers and mold engineers to ensure optimal performance.