Have you ever wondered what makes your lightweight kitchen appliances, durable luggage hardware, or even everyday cookware so functional? The unsung hero behind these products is die casting parts. Though rarely visible, these precision-crafted metal components play a vital role in countless household items. From aluminum die casting parts to zinc alloy die casting, these high-performance pieces enhance durability, efficiency, and design. Let’s explore how die casting silently shapes our daily lives.

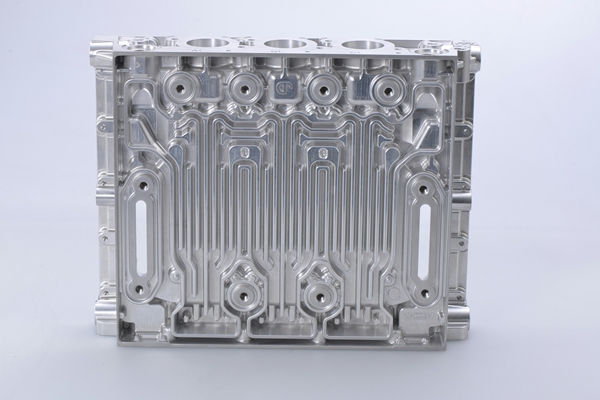

Die casting parts are metal components produced using high-pressure die casting (HPDC). In simple terms, molten metal (such as aluminum or zinc alloy) is injected at high speed into a precision mold, cooled, and ejected to form complex, high-tolerance parts.

High Precision – Tolerances as tight as ±0.1mm ensure perfect fit.

Mass Production Efficiency – Low per-unit cost (as little as a few dollars).

Complex Geometries – Intricate designs (thin walls, hollow structures, textures) that other methods can’t achieve.

The two most common materials are aluminum alloys and zinc alloys, each with unique benefits:

Lightweight – Ideal for weight-sensitive products (e.g., electronics).

Excellent Thermal Conductivity – Used in heat sinks, cooker bases.

Corrosion-Resistant – Surface treatments (anodizing) enhance durability.

High Strength – Withstands heavy loads (e.g., luggage buckles).

Superior Surface Finish – Easily plated/polished for decorative hardware.

Fluidity – Captures fine mold details for intricate designs.

Both materials support custom die casting for specialized applications.

Rice Cooker Bases – Aluminum die casting ensures stability and heat distribution.

AC Compressor Housings – Precision (±0.1mm) for seamless assembly.

Speaker Enclosures – Enhanced acoustics by minimizing sound leakage.

Die-Cast Cookware – Uniform 3-5mm thickness for even heating.

Coffee Machine Parts – Heat-resistant, lightweight aluminum alloys.

Luggage & Fashion Accessories

Zipper Pulls & Buckles – Zinc alloy offers durability + sleek finishes.

Laptop/Phone Stands – Thin-walled aluminum designs balance strength and weight.

Heat Sinks – 20-30% larger cooling surface vs. traditional designs.

Engine Blocks – Aluminum reduces vehicle weight, improving fuel efficiency.

Bathroom Fixtures – Zinc alloy with chrome plating resists rust and adds luxury.

These examples barely scratch the surface—die casting manufacturers enable innovations across industries.

Die casting parts are the invisible backbone of modern life, enhancing everything from gadgets to cars. As technology advances, die casting grows even more precise and sustainable, promising smarter, greener products.

Need die casting parts for appliances or custom die casting solutions? Partner with a trusted die casting manufacturer to bring your designs to life!