In modern high–heat-density applications—such as electronic devices, new energy vehicles, and 5G communication equipment—the performance of heat dissipation components directly determines product stability and lifespan. Among the many manufacturing processes for heat sinks, die casting has become one of the mainstream methods for producing aluminum and zinc alloy heat sinks due to its high efficiency, ability to form complex shapes, and excellent cost control.

In particular, aluminum alloy die castings, known for their outstanding thermal conductivity and lightweight properties, are often referred to as the “king of thermal conductivity” among heat dissipation materials.

Despite continuous improvements in aluminum alloy heat sink performance, manufacturers are still exploring ways to further enhance heat dissipation efficiency through innovative design and production techniques.

So, how can we improve heat dissipation from both design and manufacturing perspectives? Let’s take a closer look.

The dominance of aluminum alloys in heat dissipation applications lies in their unique physical properties. With a thermal conductivity typically ranging from 140–200 W/(m·K), aluminum offers excellent heat transfer performance. Although slightly lower than copper, aluminum is lighter, more affordable, and easier to cast into complex shapes, making it ideal for mass production.

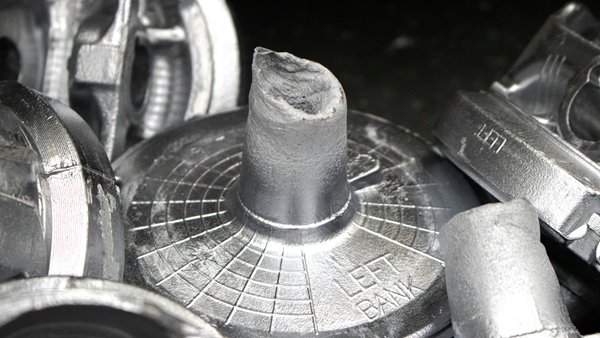

During the die casting process, molten aluminum is injected into a mold cavity at high pressure and speed, forming a dense structure with smooth surfaces. Proper heat treatment (such as aging) can further enhance thermal conductivity without compromising mechanical strength.

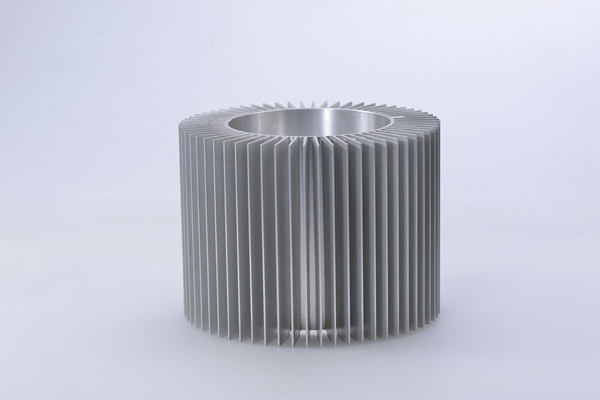

Die casting is particularly suitable for producing complex and highly integrated heat dissipation components, such as monolithic heat bases or finned heat sink modules. Both aluminum and zinc alloys are widely used, each with its own strengths:

• Aluminum alloy die castings: Excellent thermal conductivity, lightweight, corrosion-resistant—commonly used in electronics, LED lighting, and automotive cooling systems.

• Zinc alloy die castings: Superior fluidity, ideal for thin-walled and intricate parts. While their thermal conductivity is lower than aluminum, they are preferred in applications requiring higher mechanical strength.

Regardless of material choice, several production stages are crucial to ensuring product performance:

1. Mold Design and Flow Channel Optimization — Mold structure directly affects casting quality and fin density. A well-designed gating system and cooling channel can reduce porosity and shrinkage, improving consistency.

2. Control of Die Casting Parameters — Injection speed, pressure, and temperature determine how the molten metal fills the mold and the final part density.

3. Post-Processing and Surface Treatment — CNC machining, fin trimming, and anodizing enhance flatness, fin precision, and thermal radiation efficiency.

A heat sink’s performance depends not only on materials and processes but also on structural design. Below are three core directions to improve thermal performance:

(1) Enhance Heat Conduction Efficiency

According to Fourier’s law of heat conduction, increasing the conduction area, using high-conductivity materials, and applying thermal interface materials (TIMs) such as thermal grease or pads can significantly reduce thermal resistance.

For localized high-heat regions, embedding heat pipes or vapor chambers at the base can greatly improve lateral heat spreading.

(2) Strengthen Convective Heat Transfer

Since most heat is ultimately dissipated through air convection, optimizing fin geometry is crucial. Designers must balance fin height, thickness, and spacing to maximize airflow.

In forced-air cooling systems, denser fins increase surface area but also raise air resistance. Some advanced designs use angled fins, flower fins, or interrupted fin structures to guide airflow and improve overall heat transfer.

(3) Improve Radiative Heat Dissipation

For passive cooling systems, the surface emissivity of the heat sink becomes an important factor. Anodizing or black surface treatment can effectively increase infrared emissivity, enhancing heat dissipation in natural convection environments.

Modern heat sink design increasingly relies on simulation tools such as CFD (Computational Fluid Dynamics) and FEA (Finite Element Analysis). By simulating performance under different air speeds and temperatures, engineers can quickly iterate to find the optimal combination of fin layout, base thickness, and material selection.

During production, small-batch prototyping combined with thermal resistance testing provides valuable real-world data, ensuring reliable performance under actual operating conditions.

As electronic devices evolve toward higher performance and miniaturization, thermal management has become an essential aspect of product development. Aluminum alloy die castings, with their excellent balance of strength, conductivity, and manufacturability, are the ideal choice for modern heat sink production.

By optimizing design structure, selecting appropriate materials, applying precision die casting, and refining surface treatments, manufacturers can achieve higher heat dissipation efficiency and greater reliability—without increasing costs.

If you’re looking for a professional die casting manufacturer or wish to customize high-thermal-conductivity aluminum or zinc die-cast components, contact us today. We provide comprehensive thermal management solutions, from design support to mass production.