In the field of aluminum alloy die casting production, porosity has always been a key bottleneck restricting product quality improvement. Especially for structural components like automotive aluminum alloy die castings that require high airtightness and high mechanical performance, traditional die casting processes often struggle to meet the demand. Vacuum die casting technology has emerged as a core process path to achieve "zero porosity" high-density die casting production. This article will systematically analyze vacuum die casting technology from aspects such as technical principles, process flow, comparison with traditional die casting, and application prospects.

Vacuum die casting is an advanced die casting process where the gas inside the mold cavity is evacuated through a vacuum system before the molten metal fills the cavity, allowing the filling process to occur in a low-pressure or negative-pressure environment. Its core objectives are to reduce gas entrapment and lower casting porosity, thereby improving the casting's density, mechanical properties, and surface quality.

1. High Vacuum Level Control: Cavity vacuum can reach above -90 kPa, with some high-vacuum systems even below -95 kPa (absolute pressure <5 kPa), significantly reducing gas residue.

2. Combination of Low and High Speed: The initial filling stage uses low speed to push the molten metal to seal the gate, followed by high-speed filling, balancing exhaust and filling efficiency.

3. Multiple Vacuum Forms:

· Mechanical Valve Control: Automatically closes the vacuum valve via molten metal flow, achieving a full vacuum process.

· Exhaust Wave Plate: Simple structure, suitable for low-vacuum scenarios.

· Timer/Position Control: Fast system response, suitable for medium to high vacuum requirements.

The typical vacuum die casting process flow includes the following key steps:

1. Mold Clamping and Seal Detection: After the mold is clamped, ensure key areas like the parting line, sliders, and ejector pins are well sealed.

2. Vacuum Startup: After the injection plunger seals the pouring hole, the vacuum system starts, rapidly evacuating gas from the cavity.

3. Multi-Stage Injection Filling:

· Slow Speed Phase: Pushes molten metal forward smoothly to avoid splashing.

· Fast Speed Phase: High-speed filling of the cavity under vacuum.

· Intensification and Holding Pressure: Increases internal density and compensates for shrinkage.

4. Vacuum Valve Closure: At the end of filling, the vacuum valve is closed via molten metal, mechanical signal, or timer control to prevent metal backflow.

5. Cooling, Mold Opening, and Post-Processing: The casting is removed after cooling for subsequent steps like trimming, heat treatment, and machining.

Aspect | Traditional High-Pressure Die Casting | Vacuum Die Casting |

Gas Entrapment | 40%~90% of molten metal contacts gas, resulting in high porosity | 80%~90% of gas is evacuated beforehand, leading to a lower probability of gas entrapment |

Vacuum Level | No active exhaust; relies on overflow wells and vents | Cavity vacuum can reach above -75 kPa, with high vacuum reaching -95 kPa |

Casting Performance | Poor airtightness, difficult to weld and heat treat | Weldable, capable of T6 heat treatment, with significantly improved mechanical properties |

Mold Life | High filling pressure leads to faster mold wear | Filling pressure is 30%~50% lower, extending mold life |

Cost Structure | High proportion of overflow wells and recycled material, resulting in low material utilization | Lower proportion of overflow wells, recycled material reduced by over 20% |

With the acceleration of automotive lightweighting, automobile aluminum alloy die castings are developing towards larger size, integration, and higher performance. Components such as body structural parts, battery pack housings, and suspension systems require not only weight reduction but also properties like high strength and toughness, high airtightness, weldability, and heat treatability.

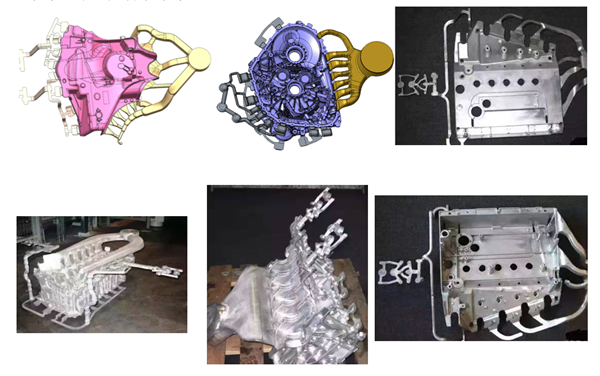

By reducing porosity and improving material density, vacuum die casting enables aluminum alloy die castings to meet higher safety and performance requirements. Currently, many leading aluminum alloy die casting manufacturers widely use high-vacuum die casting technology to produce key components like front/rear longitudinal beams, shock towers, and door frames, even achieving integrated floor casting, significantly reducing part count and assembly steps.

Vacuum die casting technology continues to evolve. Directions such as high vacuum + multi-stage evacuation, real-time in-mold vacuum monitoring, and intelligent closed-loop process control are pushing "zero porosity" castings closer to mass production reality. With increasing die casting machine clamping force (now exceeding 10,000 tons), improvements in mold sealing technology, and optimization of alloy materials, vacuum die casting will play a greater role in areas like new energy vehicles, 5G communications, and aerospace.

Vacuum die casting is not merely about adding an exhaust system; it is a systematic engineering project encompassing mold design, sealing technology, process control, and material matching. For aluminum alloy die casting manufacturers pursuing high quality and reliability, mastering vacuum die casting technology is not only key to enhancing competitiveness but also an inevitable choice in responding to the trends of automotive lightweighting and green manufacturing.

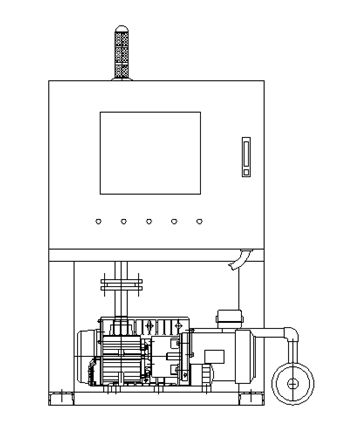

If you are looking for a reliable partner for precision component customization and die casting production, EDT Die Casting Technology (Suzhou) Co., Ltd. is your ideal choice.

We specialize in zinc and aluminum alloy die casting, equipped with advanced European die casting technology and management systems. Our fully automated melting, die casting, machining, and inspection equipment ensure every product meets high-quality standards.

Whether it's complex structural parts, high-precision housings, or components with special material performance requirements, we can provide you with a one-stop solution from mold development to finished product delivery through scientific process design and rigorous production control.

Choosing EDT means choosing quality, efficiency, and trust!